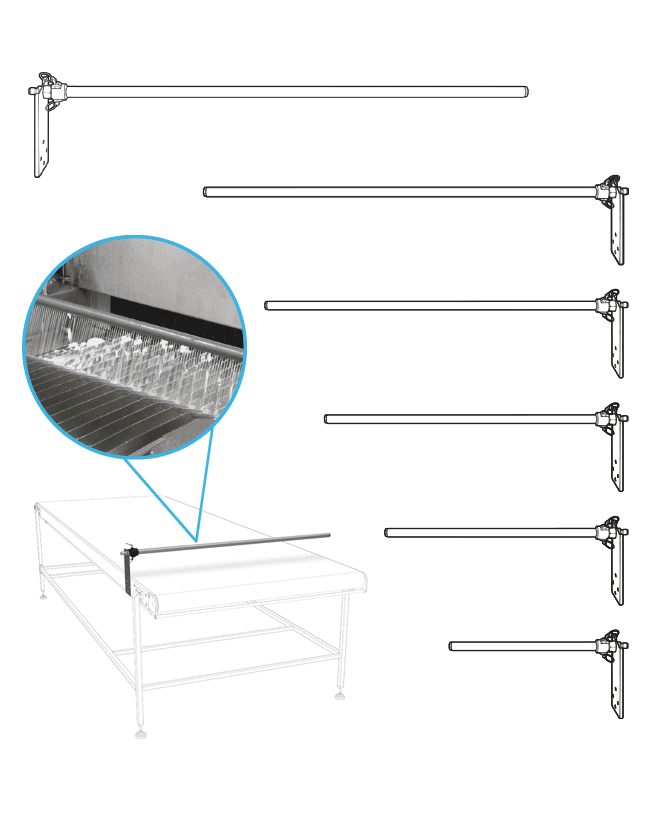

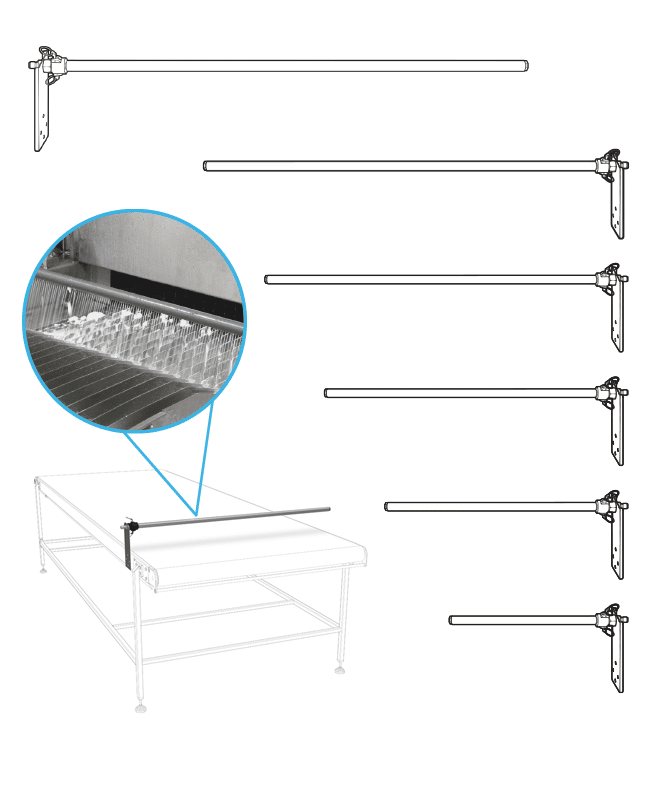

Belt Foam Bar Attachments

#BFS-BA-##Available in six different sizes, belt foam bars make belt cleaning quicker and more affordable. Provides complete belt coverage and mounts to the conveyor.

Available in six different sizes, belt foam bars make belt cleaning quicker and more affordable. Provides complete belt coverage and mounts to the conveyor.

with 3/4 in. (19 mm) hose: 20-30 gal/min (75.7-113.6 l/min)

with 3/4 in. (19 mm) hose: 2-2.25 gal/min (7.6-8.5 l/min)

18-48 in. (0.5-1.2 m) width beneath the bar

*dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.

40-100°F (4.4-37.8°C)

requires connection to a FOAMit unit with ¾ in. (19 mm) discharge hose and a ½ in. FPT discharge ball valve

Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

We have distributors all over the world. Tell us a little bit about you and your equipment needs, and we’ll help you find or become a distributor.

We can’t clean your inbox, but we can help keep it interesting. Stay in the know on products, improvements, and other news.