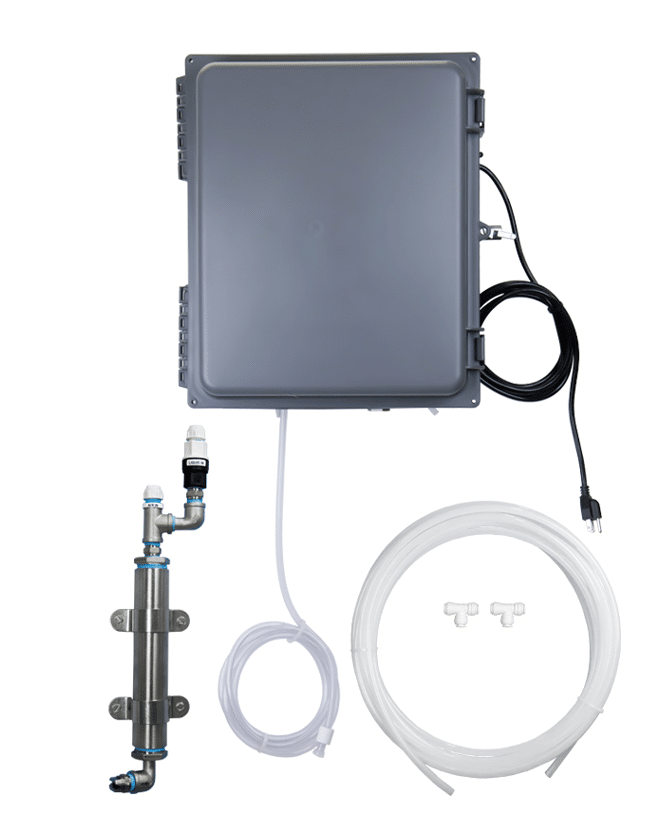

Twin-Line Concentrate Doorway Foam Unit

#DS4Wall mounted, air and electricity powered, twin-line concentrate foam unit for doorways. Supports up to three twin-line nozzle assemblies with 100ft total distance and repeat cycle timers.

Wall mounted, air and electricity powered, twin-line concentrate foam unit for doorways. Supports up to three twin-line nozzle assemblies with 100ft total distance and repeat cycle timers.

compressed air, electricity

draws from concentrated product

38:1 to 183:1

one product

8 ft. (2.4 m) clear hose with 1/4 in. (6.4 mm) inside diameter

2 gal/min (7.6 l/min)

Santoprene, Viton, or Kalrez

repeat cycle

one nozzle: up to 9×5 ft. (2.7×1.5 m);

two nozzles: up to 8×4 ft. (2.4×1.2 m) at each nozzle;

three nozzles: up to 6×3 ft. (1.8×0.9 m) at each nozzle

one nozzle: ST80200SS;

two nozzles: ST80100SS;

three nozzles: ST8060-12SS

twin-line stainless steel nozzle assembly (NZA-DS-TL-1)

one control box can support up to three nozzle assemblies

the combined distance between the control box and the nozzle(s) must equal 100 ft. (30.5 m) or less

Designed for use with 1/2 in. (12.7 mm) outside diameter tubing between control box and nozzle(s)

*dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.

40-80 psi (2.8-5.5 bar) with 5-10 cfm (141.6-283.2 l/min)

10-100 psi (0.7-6.9 bar)

backflow prevention is required – consult local plumbing ordinances for more information.

40-100˚F (4.4-37.8˚C)

120 VAC at 60 Hz, 2 amps (GFCI protected outlet)

120 VAC

Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

| PUMP SEAL MATERIAL | NUMBER OF NOZZLES | ||

|---|---|---|---|

| DS4 | Santoprene (standard) | – | One (standard) |

| Viton (V) | Two (2) | ||

| Kalrez (K) | Three (3) |

Add option codes to item number as shown. For standard options, no option code is needed. Examples:

also available in a version for 2-part products >>

Choose a pump seal material that is compatible with the chemicals you will use. Chemical incompatibility can cause accelerated wear and equipment failure that is not covered by warranty, so it’s important to do your research.

We have distributors all over the world. Tell us a little bit about you and your equipment needs, and we’ll help you find or become a distributor.

We can’t clean your inbox, but we can help keep it interesting. Stay in the know on products, improvements, and other news.