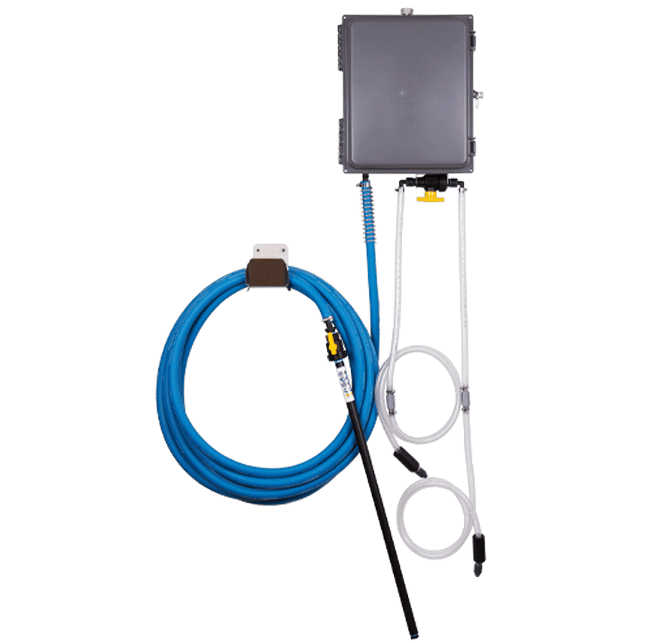

High Concentration Foam Unit with 2-Product Selector and All-Poly Fittings

#FI-WC-11-AP-2PSELWall mounted, air-powered, high concentrate foam unit that can draw from two products and has all-poly fittings. Option to switch between two products using 3-way selector ball valve.