- power type

compressed air

- chemical pickup type

draws from concentrated product

- dilution ratio range*

8:1 to 150:1 for each product

note: dilution rate can be set independently for each product

- number of products unit can draw from (and whether it draws simultaneously or one at a time)

two products, simultaneously

- suction line length/diameter

two suction lines, each 8 ft. (2.4 m) of clear hose with 1/4 in. (6.4 mm) inside diameter

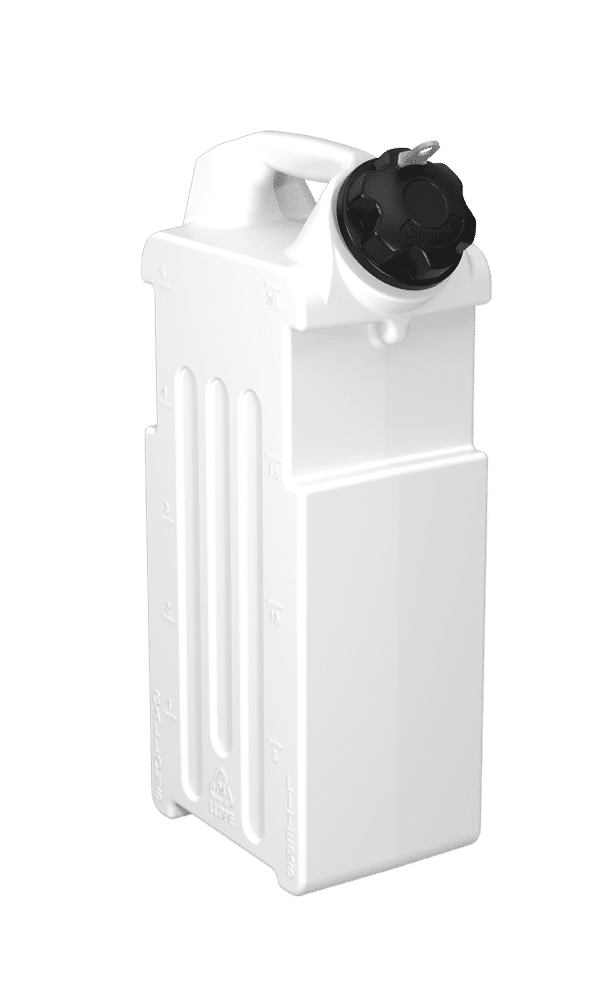

- capacity

15 gallons (56.8 liters) of water; Up to 10 gallons (37.9 liters) of concentrate

- discharge hose length/diameter

30 ft. (9 m) hose, with 3/4 in. (19 mm) inside diameter

- discharge wand/tip type

7 in. (17.8 cm) stainless steel wand with zero tip and ball valve

- output distance

25-30 ft. (7.6-9.1 m)

- output volume

20-45 gal/min (75.7-170.3 l/min)

- flow rate*

2-2.25 gal/min (7.6-8.5 l/min)

- pump seals

Santoprene, Viton, or Kalrez

- wheel type

two 10 inch (25.4 cm) non-marking wheels and two 5 inch (12.7 cm) casters, one with lock

*dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.