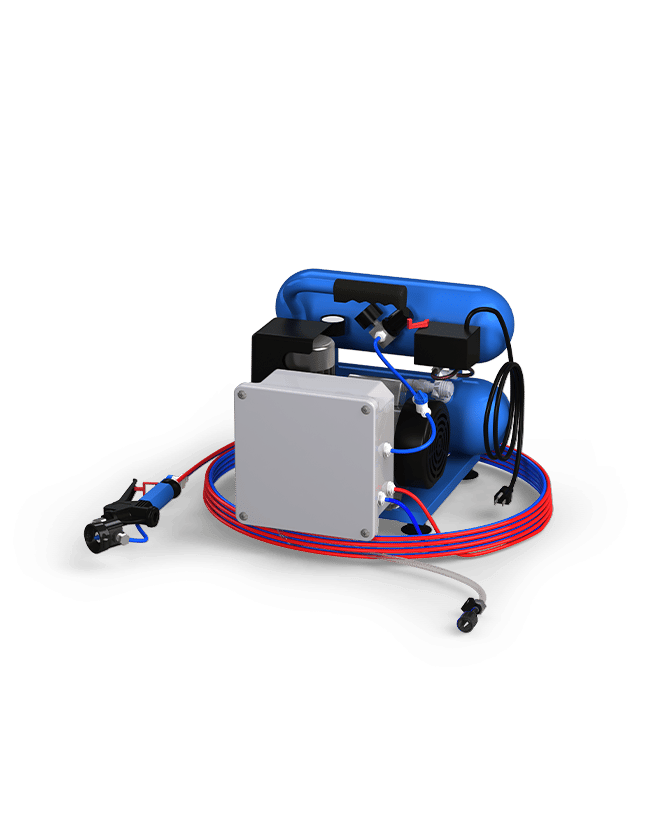

Pre-Mix Electric Mist Unit

#MU-JR-PSGN130-H50Powered by a built in 120 VAC electric compressor this unit applies disinfectants and other chemistry with a handheld wand.

Powered by a built in 120 VAC electric compressor this unit applies disinfectants and other chemistry with a handheld wand.

electricity

draws from pre-mixed solution

one product

6 ft. (1.8 m) clear hose with 1/4 in. (6.4 mm) inside diameter

50 ft. (15.2 m) twin-line tubing 1/4 in. (6.4 mm) outside diameter

polypropylene trigger handle for liquid output and polypropylene mist nozzle with Kynar tip

3.4.5 ft (0.9-1.4 m)

8.96 oz/min at 50 psi (3.4 bar) – static

8.96 oz/min at 50 psi (3.4 bar) – static

Santoprene, Viton, or Kalrez

15 microns at 50 psi (3.4 bar)

1 liter of solution will cover approximately 1000 cubic feet

pneumatic mist nozzle

one

*dilution rates and flow rates given are based on chemical with viscosity of water and factory air pressure settings.

50-80 psi (3.4-5.5 bar)

40-100°F (4.4-37°C)

Chemical products used with this equipment must be formulated for this type of application and compatible with unit materials and pump seals. For more information on chemical compatibility, consult the manufacturer or SDS for your product or contact our customer service department.

| PUMP SEAL MATERIAL | HOSE LENGTH | ||

|---|---|---|---|

| MU-JR | Santoprene (standard) | – | 50ft (PSGN130-H50) |

| Viton (V) | 100ft (PSGN130-H100) | ||

| Kalrez (K) | 150ft (PSGN130-H150) |

Add option codes to item number as shown. For standard options, no option code is needed.

Example:

Choose a pump seal material that is compatible with the chemicals you will use. Chemical incompatibility can cause accelerated wear and equipment failure that is not covered by warranty, so it’s important to do your research.

We have distributors all over the world. Tell us a little bit about you and your equipment needs, and we’ll help you find or become a distributor.

We can’t clean your inbox, but we can help keep it interesting. Stay in the know on products, improvements, and other news.